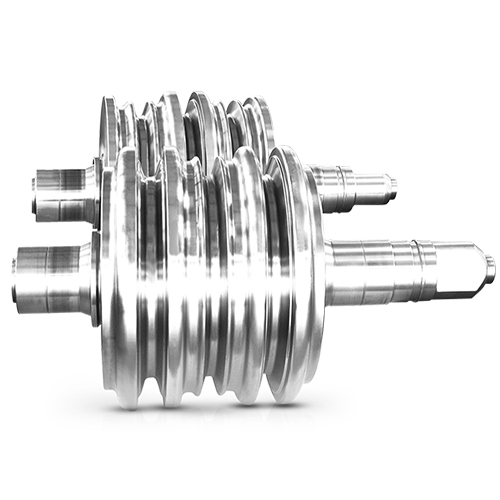

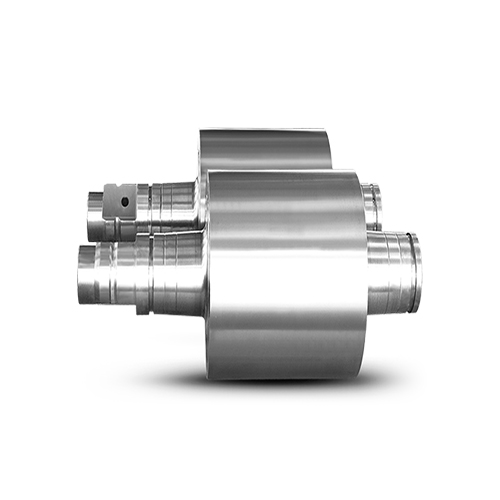

Graphtie Steel Rolls

| Name: | Graphtie Steel Rolls |

|---|

Graphite steel rolls are roll material that provides better performance in specific rolling applications. It can serve various purposes in both the section steel rolling mill and hot-rolled plate and strip production.

Product Description

Product Description

Here are some characteristics and applications:

1. Improved Resistance to Thermal Cracking: Due to the high thermal conductivity of graphite, graphite steel rolls may exhibit good resistance to thermal cracking, especially in high-temperature environments commonly encountered in rolling operations.

2. Enhanced Anti-Oxidation and Iron Scale Adhesion Resistance: The lubricating properties of graphite can contribute to reducing the adhesion of oxidation and iron scale on the roll surface, improving anti-oxidation and scale adhesion resistance. This is crucial for maintaining a clean roll surface and extending the roll's service life.

3. Suitability for Roughing and Intermediate Rolling Stands: Given the potential for good heat resistance and lubrication, graphite steel rolls are more suitable for roughing and intermediate rolling stands where high temperatures and heavy loads are often encountered.

Chemical Composition

|

Code |

C |

Si |

Mn |

Cr |

Ni |

Mo |

|

GS140 |

1.30-1.50 |

1.30-0.80 |

0.50-1.00 |

0.40-1.00 |

0.20-1.00 |

0.20-0.60 |

|

GS160 |

1.50-1.70 |

0.80-1.50 |

0.60-1.20 |

0.50-1.50 |

0.20-1.00 |

0.20-0.80 |

|

GS190 |

1.80-2.00 |

0.80-1.50 |

0.60-1.20 |

0.50-2.00 |

0.70-2.20 |

0.30-0.80 |

|

GS210 |

2.00-2.20 |

0.80-1.50 |

0.6-1.20 |

1.00-2.50 |

1.50-2.60 |

0.40-1.00 |

|

GS240 |

2.30-2.50 |

0.80-1.50 |

0.80-1.50 |

1.00-2.50 |

1.50-3.00 |

0.80-1.50 |

Techinical Specification

|

Code |

Hardness HS |

Tensile Strength Mpa |

Elongation % |

Dimension mm |

Weight kg |

|

GS140 |

36-46 |

≥540 |

≥1.0 |

≤1300 |

1000~30000 |

|

GS160 |

45-55 |

≥500 |

≥1.0 |

||

|

GS190 |

50-65 |

≥450 |

≥0.4 |

||

|

GS210 |

55-70 |

≥450 |

≥0.4 |

||

|

GS240 |

60-75 |

≥450 |

≥0.4 |

In summary, graphite steel rolls are material that provides better performance in specific rolling applications. It can serve various purposes in both the section steel rolling mill and hot-rolled plate and strip production. Here are some potential recommended applications:

1. Section Steel Rolling Mill:

• Roughing rolls

• Intermediate rolls

• Finishing rolls

• Horizontal roll rings

• Vertical roll rings

• Straightening rolls

• Edge rolls

2. Blooming Mill Rolls:

• Rolls suitable for the blooming mill stands, including roughing rolls and others.

3. Hot-Rolled Plate and Strip:

• Roughing rolls

• Vertical rolls

These rolls play different roles in the production process, from rough rolling to intermediate and finishing rolling, as well as straightening and edge rolling. Each stage has specific requirements. The advantages of graphite steel rolls, such as resistance to thermal cracking and anti-oxidation properties, make them a favorable choice for handling high-temperature and high-load environments.

Of course, the specific selection depends on the details of the production process, the dimensions of the rolls, and the material and quality requirements. When selecting rolls, it is advisable to have detailed discussions with GoldenROLLS to ensure that the chosen rolls meet your specific needs.

Related Products

Alloy Steel Rolls

Alloy Steel Rolls are ideal for roughing stands of HSM and serving as back up rolls of hot strip mills, dut to it's excellent characteristics..

Read more >>

Adamite Rolls

Adamite rolls are commonly used in hot rolling mills, where they are subjected to the high temperatures and mechanical stresses of shaping metal into various forms, such as sheets, bars, or rails.

Read more >>

Hot Working Die Steel Rolls

Hot working Die steel rolls possess high thermal strength, excellent thermal stability, good wear resistance, resistance to cold and thermal fatigue, and stable resistance to tempering.

Read more >>