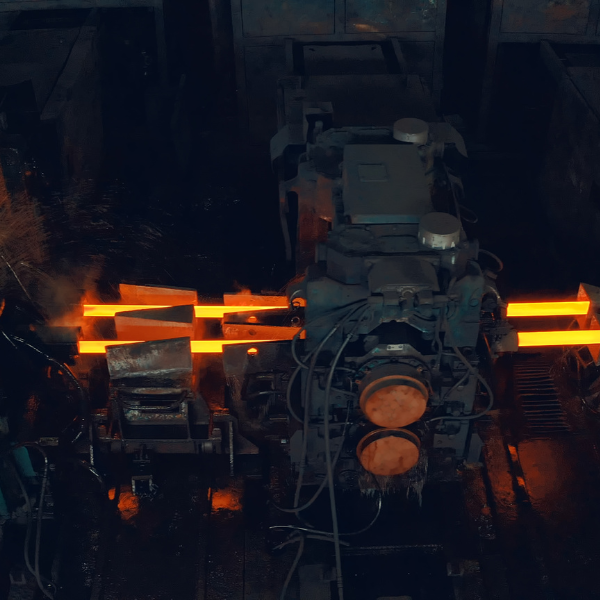

In the steel and metallurgical industries, the rolling mill is a cornerstone of production. Among its many parts, the rolling mill rolls and rolling mill bearings stand out as the most critical components, directly determining both efficiency and quality.

Rolls in Rolling Mill

Rolls serve as the main deformation tool in the rolling process. As they come into direct contact with the metal, they apply pressure that causes plastic deformation, shaping the material into the desired thickness and profile. The performance of rolls, including their hardness, wear resistance, and surface quality, is essential to achieving precise product specifications and consistent output.

The quality and service life of rolls directly tied to the mill’s overall productivity. High-performance rolls not only improve product quality but also extend maintenance intervals and reduce production costs. SATRAD GROUP is a leading supplier of rolls for rolling mills. Our product portfolio includes mill rolls such as cast steel rolls, cast iron rolls, and forged steel rolls.

What is Mill Roll?

The rolls are the core working components of rolling mills, consisting of the roll body and journals. During the rolling process, rolls come into direct contact with the metal, applying pressure through rotation to induce plastic deformation. This process shapes the material into the required cross-sectional dimensions, forms, and surface quality.

Classification of Rolling Mill Rolls

Rolls can be classified according to different criteria:

1. By Manufacturing Method

- Cast Steel Rolls: Produced by casting, offering high strength, suitable for heavy-duty conditions.

- Cast Iron Rolls: Dense microstructure with excellent wear resistance and thermal crack stability. Available in chilled, high-chromium, or nodular iron variants, commonly used in finishing mills.

- Forged Steel Rolls: Manufactured by forging, featuring uniform and compact structure with strong load-bearing capacity.

- Carbide Rolls: Ultra-hard and wear-resistant, perfect for high-precision, high-hardness metals.

2. By Application

Work Rolls: Directly contact the metal, completing the plastic deformation process.

Hot Rolling Rolls: Used in high-temperature rolling for primary shaping and hot forming of metals.

Cold Rolling Rolls: Applied in precision rolling at room temperature, ensuring surface quality and dimensional accuracy.

Backup Rolls: Designed to bear rolling forces and maintain stability during operation.

3. By Product Type

- Strip Rolls: Designed for rolling hot-rolled and cold-rolled strips, our cylindrical strip rolls ensure excellent surface finish and dimensional accuracy, guaranteeing superior strip quality.

- Section Rolls: Tailored for structural steel like I-beams, channels, and angles, these rolls feature precisely grooved surfaces to meet complex cross-sectional requirements.

- Wire Rod Rolls: Engineered for wire rods, rebars, and steel wires, these rolls offer high wear resistance and surface hardness, ensuring consistent quality in high-volume production.

4. By Position in the Rolling Mill

- Blooming Rolls: Ideal for initial shaping of ingots and billets into semi-finished products, designed to withstand high loads with superior strength and wear resistance.

- Roughing Rolls: Positioned after blooming rolls, they progressively shape semi-finished products closer to final dimensions while maintaining stability under high rolling forces.

- Finishing Rolls: Delivering the final precision and surface finish, our finishing rolls meet strict dimensional and quality standards, ensuring top-grade finished steel.

5. By Rolling Condition

- Hot Rolls: Engineered for high-temperature hot rolling, with exceptional heat and wear resistance.

- Cold Rolls: Precision rolls for cold rolling, ensuring exact dimensions, superior surface finish, and long-term durability.

6. By Roll Shape

- Cylindrical Rolls: Standard for plates, strips, sections, and wires, combining reliability with versatility.

- Non-Cylindrical Rolls: Conical, barrel, and disk shapes designed for specialized tube rolling or unique profiles.

Why Choose SATRAD GROUP Rolls?

- Optimized for durability, precision, and performance.

- Customizable materials, shapes, and surface treatments to match your production needs.

- Advanced manufacturing processes ensure longer service life and lower operational costs.

- Trusted partner for hot, cold, and specialty steel production worldwide.