SATRAD GROUP supply premium quality carbon anode blocks for Electrolysis Operations. Our carbon blocks meet ISO 9001 & ASTM standards, with customizable specs to fit your unique electrolysis needs.

What is Carbon Anode Block?

Prebaked anodes are used as anode materials in pre-baked aluminum electrolytic cells in smelters. They are produced using petroleum coke and pitch coke as aggregates, bonded with coal tar pitch. After baking, these carbon blocks acquire a stable geometric shape, hence they are also called prebaked anode carbon blocks and are conventionally referred to as carbon anodes for aluminum electrolysis.

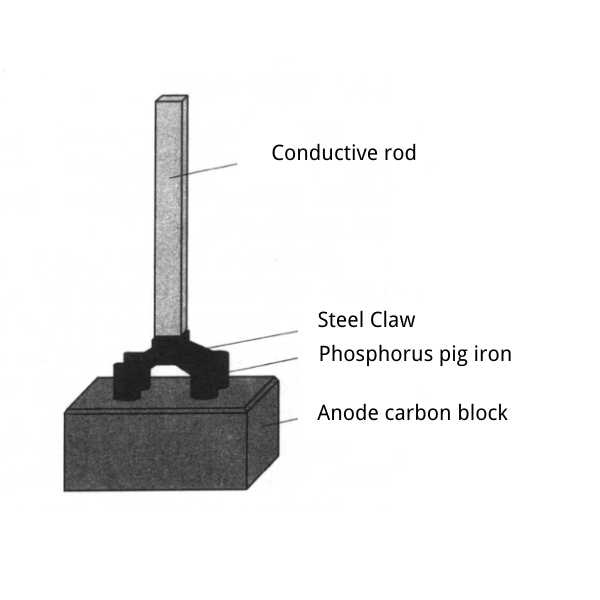

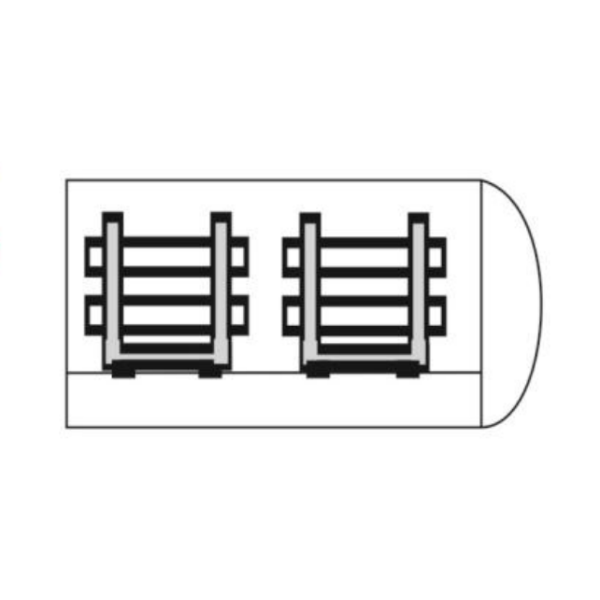

Anode carbon blocks are typically rectangular cuboids, featuring 2 to 4 bowls on their upper surface. These carbon bowls measure 160~180 mm in diameter and 80–110 mm in depth. During anode assembly, the carbon bowls accommodate the anode stubs, which are then connected to the anode via phosphorous pig iron casting, forming an integrated carbon block assembly.

The dimensions of anode carbon blocks vary based on the electrolytic cell’s current capacity. They generally operate at a current density of 0.70–0.90 A/cm² and have a life cycle of 20–28 days.

Properties of Carbon Anode Blocks

| Grade | Apparent Density g/cm³ | True Density g/cm³ | Compressive Strength MPa | CO₂ Reactivity (Residual Pole Rate) % | Flexural Strength MPa | Room Temperature Resistivity μΩ·m | Thermal Expansion Coefficient K | Ash Content % |

| Not less than | Not more than | |||||||

| TY – 1 | 1.56 | 2.05 | 35 | 85 | 9 | 57 | 4.5×10⁻⁶ | 0.5 |

| TY – 2 | 1.53 | 2.03 | 32 | 80 | 8 | 62 | 5.0×10⁻⁶ | 0.7 |

Note: When the buyer has special requirements for physical and chemical properties other than those parameters we provide, such as thermal conductivity, elastic modulus, air reactivity, air permeability, and trace element contents (sulfur, vanadium, nickel, silicon, iron, sodium, calcium, titanium), etc., they shall be determined through consultation between the SATRAD GROUP and the user and specified in the contract.

Manufacturing Process of Carbon Anode Blocks

The production process of anode materials includes the pre-crushing, calcination, crushing, screening, classification, and batching of raw materials such as petroleum coke, pitch coke, and spent anode; the pretreatment and mixing of binders; as well as the molding, roasting, and cleaning processing of the paste after mixing.

1. Raw Material Preparation

- Pre-crushing of raw materials (e.g., petroleum coke, pitch coke, butts (spent anodes))

- Calcination of coke to remove volatiles and improve conductivity

- Crushing, screening, and grading to achieve desired particle size distribution

- Formulation of aggregates

2. Binder Preparation

- Pre-treatment of coal tar pitch to adjust viscosity and softening point

3. Mixing & Kneading

- Kneading of dry aggregates with heated binder to produce homogeneous green paste

4. Forming

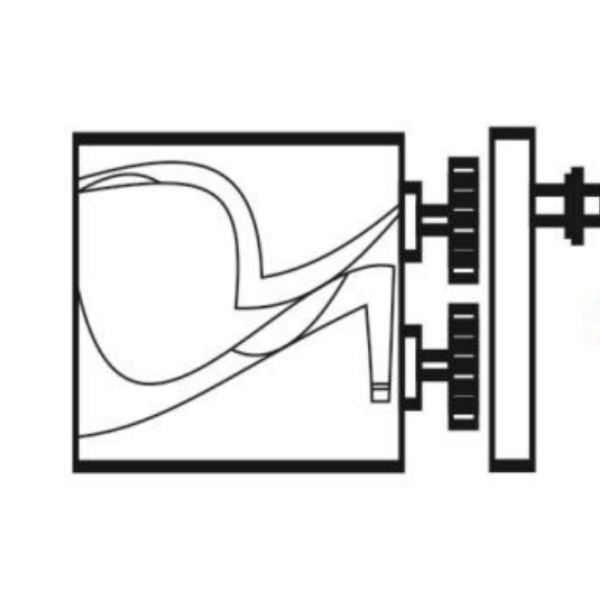

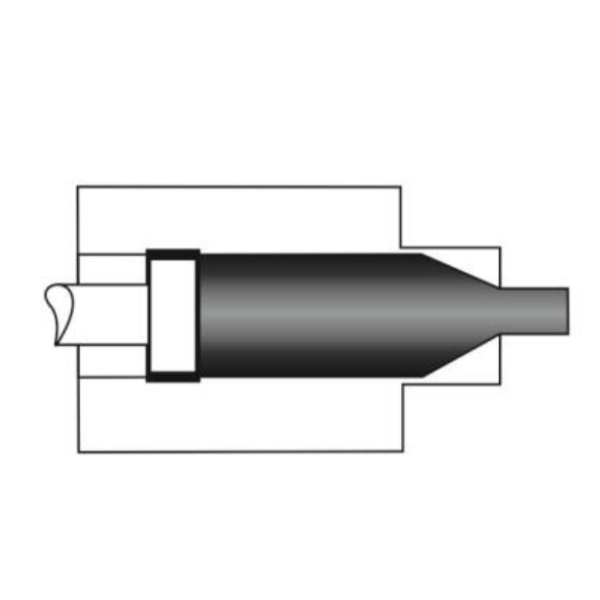

- Molding (vibro-compaction or extrusion) of the paste into green blocks

5. Baking

- Firing of green blocks in baking furnaces (typically 1100-1200°C) to carbonize binder and develop mechanical strength

6. Finishing

- Machining to final dimensions

- Quality inspection (density, resistivity, strength testing)

Raw Materials Used in the Manufacture Process

1. Petroleum Coke

- Green (raw) petroleum coke is sourced from oil refineries as a byproduct of delayed coking units, where residual oil undergoes thermal cracking. Also known as delayed coke, it serves as the main raw material for anode production in aluminum smelters.

- Petroleum coke is preferred for carbon anode manufacturing due to its:

- High purity (low metal/ash content)Excellent mechanical strengthGood electrical conductivity

- Besides delayed coke, refineries also produce fluid coke, a lower-grade coke derived from heavy oil through fluidized-bed coking.

2. Pitch Coke

- An alternative raw material is pitch coke, produced from the pyrolysis and coking of coal tar pitch

- Compared to petroleum coke, pitch coke has:

- Lower volatile matte

- Higher density and mechanical stability

3. Calcined Petroleum Coke (CPC)

- Green petroleum coke contains high moisture (5-10%) and volatile matter (8-12%), along with trace metallic and non-metallic impurities

- Its low true density, poor strength, and high electrical resistivity make it unsuitable for direct anode production.

- Calcination at 1250–1350°C removes volatiles and improves:

- Mechanical strengthTrue density

- Electrical conductivity

- Higher bulk density of CPC correlates with better anode quality.

4. Coal Tar Pitch (Binder)

Coal tar pitch is particularly suitable as a binder for carbon and graphite products in ferrous and non-ferrous metallurgical industries due to its:

- High carbon content (typically 92-95 wt%)

- Excellent binding properties (softening point 80-110°C for optimal impregnation)

- High purity after carbonization (ash content <0.3% after 1200°C treatment)

- Low production cost (byproduct of coke oven gas purification)

This makes it the dominant binder choice for:

✓ Prebaked anodes (aluminum electrolysis)

✓ Graphite electrodes (steelmaking EAF)

✓ Carbon blocks (Mg/Pb/Zn smelting)

✓ Cathode pastes (aluminum reduction cells)

5. Anode Butts

Butts (spent anodes) serve as another carbon source for manufacturing prebaked anodes in aluminum electrolysis. When butts are utilized as raw material for anode production, the adhering electrolyte crust must first be thoroughly removed.

In standard practice, recycled butts from electrolytic cells are processed together with calcined petroleum coke. Typically, the cleaned butts are crushed and blended into the new anode formulation as part of the coarse aggregate fraction in the dry mix.

Packaging

Pre-baked anode products can be simply packaged with plastic film, or other packaging methods can be agreed upon by both the supplier and the buyer.

Transportation and Storage

Pre-baked anodes should be kept clean and dry during transportation and storage to avoid moisture and damage.

Order From Us

Our high-performance prebaked anodes are engineered with:

✅ Fixed carbon content ≥95% (up to 98% for high-end grades) with minimal impurities

✅ High Strength & Wear Resistance

✅ Tailored dimensions to fit your electrolytic cells perfectly

Get Your Free Custom Quote Today

Kindly reach out to us, and our technical team will:

- Analyze your specific smelting process needs

- Recommend the optimal anode specs for your plant

- Provide a competitive, transparent pricing plan

📞 Call us now: +86 13184770996

📧 Email: info@satradco.com

Your Reliable Prebaked Anode Supplier — SATRAD GRUOP!