What is Graphite Electrode?

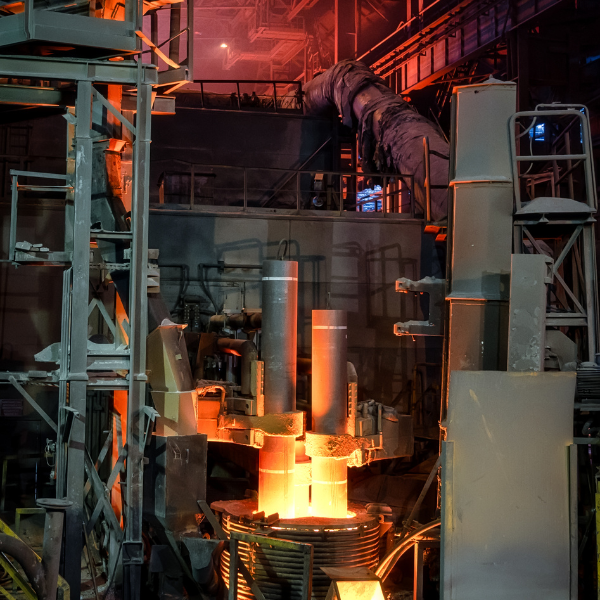

Graphite electrodes are essential conductive components in electric arc furnace (EAF) steelmaking processes. They transmit electrical energy into the furnace, generating a high-temperature arc between the electrode columns and steel scraps. This intense heat melts steel scraps, enabling efficient steel production.

Types and Characteristics

In electric arc furnace (EAF) steel production, graphite electrodes are categorized into three grades based on power requirements: Regular Power (RP), High Power (HP), and Ultra-High Power (UHP). Each type offers distinct performance characteristics to meet different operational needs in the steelmaking process.

1. Regular Power (RP) Graphite Electrodes

RP electrodes are made from standard-grade petroleum coke and undergo graphitization at lower temperatures. They have higher electrical resistivity and lower thermal shock resistance compared to premium-grade electrodes. These are typically used in low-to-medium power EAF operations where extreme performance demands are not required.

2. High Power (HP) Graphite Electrodes

HP electrodes are manufactured using high-quality petroleum coke blended with low-density needle coke, resulting in better conductivity and strength than RP electrodes. Their improved microstructure allows for higher current loads and better thermal stability, making them suitable for high-power EAF applications that demand greater efficiency

3. Ultra-High Power (UHP) Graphite Electrodes

UHP electrodes are the top-tier option, produced with premium petroleum coke and high-density needle coke. They undergo extreme graphitization (2800–3000°C), giving them ultra-low electrical resistance, exceptional current density capacity, and superior resistance to thermal stress. These electrodes are engineered for the most demanding EAF operations, where extreme thermal and electrical loads are encountered..

Manufacturing Process of Graphite Electrodes

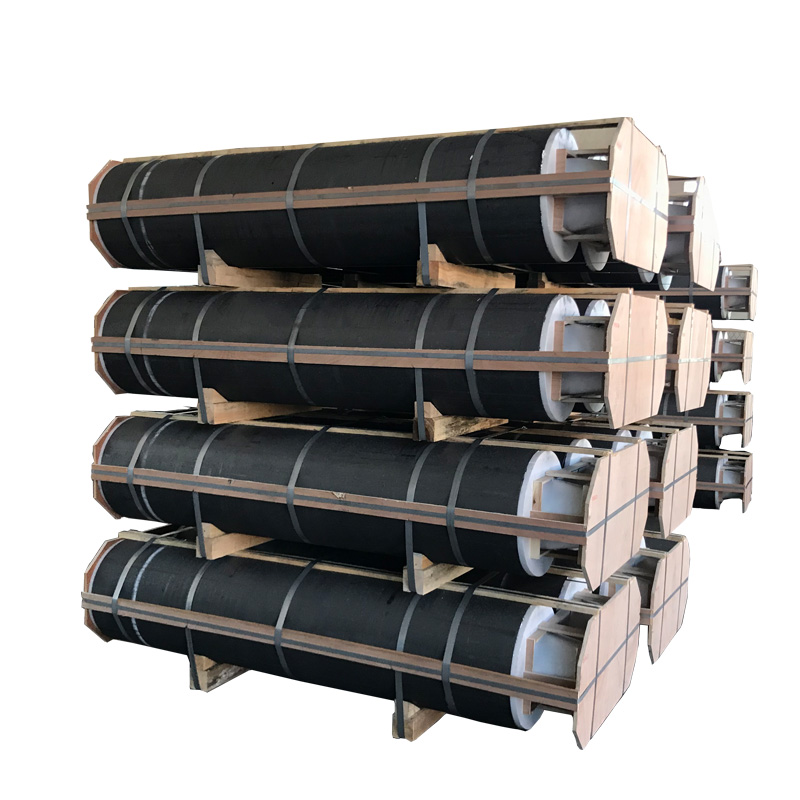

Graphite electrodes are manufactured using premium petroleum coke and pitch coke as aggregates, with coal tar pitch as a binder.

The production of high-quality graphite electrodes involves multiple precise steps, including calcination, crushing, mixing, Kneading,forming, baking, impregnation (optional), graphitization, and machining. Below is a detailed breakdown of the manufacturing process.

1. Calcination

Raw Materials: Petroleum coke or pitch coke.

Temperature: Above 1300°C.

Purpose: Removes volatile components, increases true density, mechanical strength, and electrical conductivity.

The raw coke is heated in a high-temperature furnace to eliminate moisture, sulfur, and other impurities, resulting in a more stable carbon structure.

2. Crushing, Screening & Mixing

The calcined coke is crushed and sieved into different particle sizes (coarse, medium, and fine fractions).

A portion is ground into fine powder.

The particles are precisely weighed and mixed according to the formulation.

3. Kneading (Mixing with Binder)

- The dry mixture is heated and blended with a binder (typically coal tar pitch) to form a paste.

- Temperature, mixing time, and binder influence the paste’s quality and final product quality.

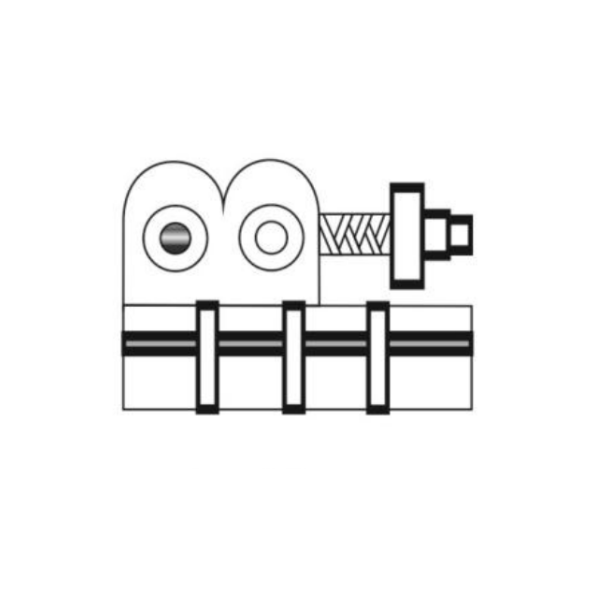

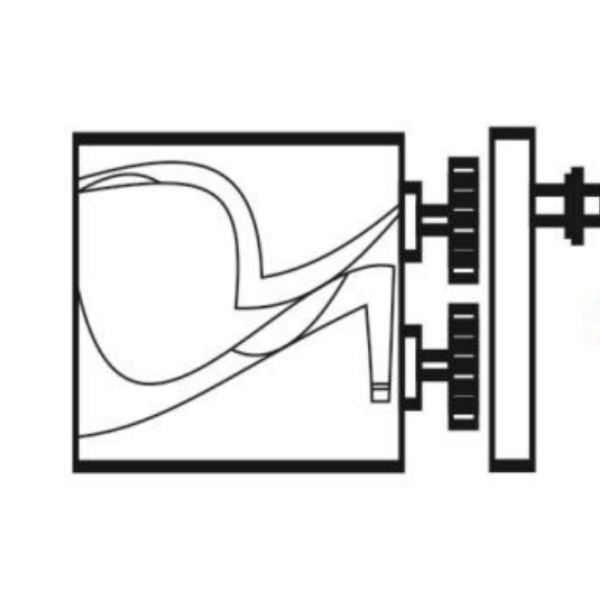

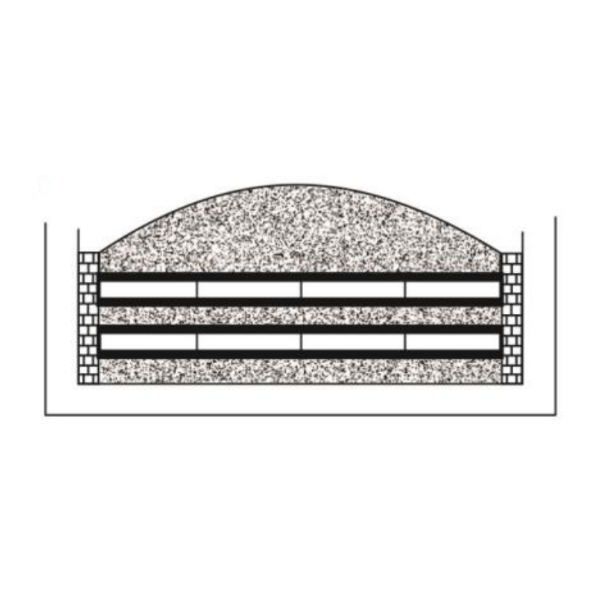

4. Forming (Molding)

- The paste is shaped into “green” electrodes using:

- Extrusion (for cylindrical electrodes)

- Vibration Molding (for large-diameter electrodes)

- Compression Molding (for special shapes)

- The formed green electrodes have high density but require further heat treatment for structural stability.

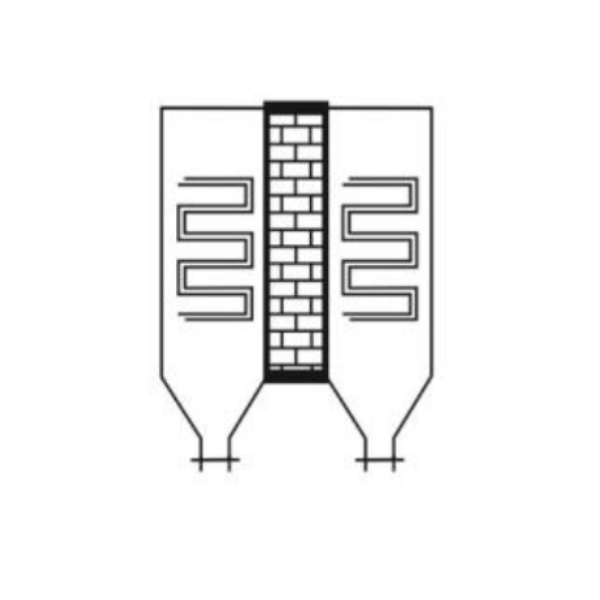

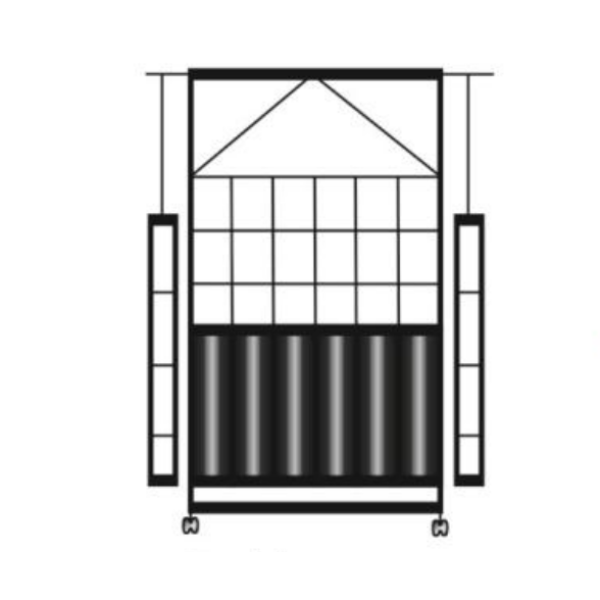

5. Baking (Carbonization)

- The green electrodes are baked in a furnace at 850–1000°C under a protective filler (coke or sand) to prevent oxidation.

- The binder undergoes carbonization, transforming into a solid carbon matrix that binds the coke particles.

- The baked electrodes (now called “carbonized electrodes”) gain mechanical strength.

6. Impregnation (Optional – For High-Density Electrodes)

- To enhance density and strength, the baked electrodes are placed in an autoclave, where liquid pitch or resin is forced into the pores under high pressure.

- After impregnation, the electrodes undergo secondary baking to carbonize the impregnated binder.

- This process may be repeated 2–3 times for ultra-high-density electrodes.

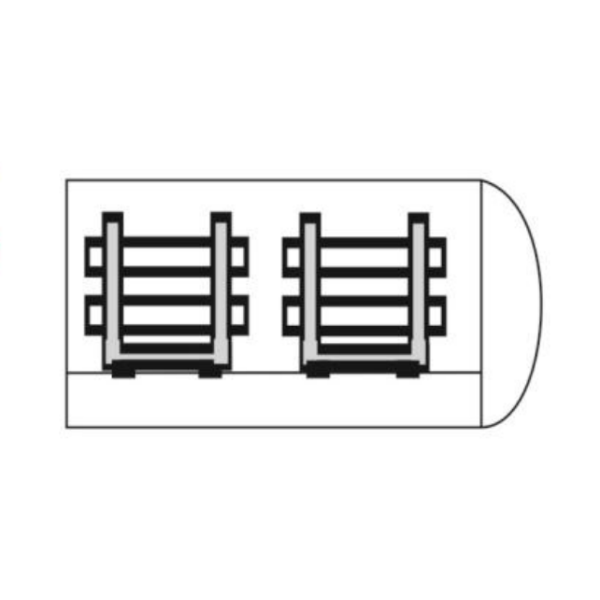

7. Graphitization

The carbonized electrodes are loaded into a graphitization furnace, covered with insulating material, and heated to 2000–3000°C via direct electric current (Acheson process or LWG method).

- At this extreme temperature, the amorphous carbon structure transforms into a crystalline graphite lattice, significantly improving:

- Electrical conductivity

- Thermal resistance

- Oxidation resistance

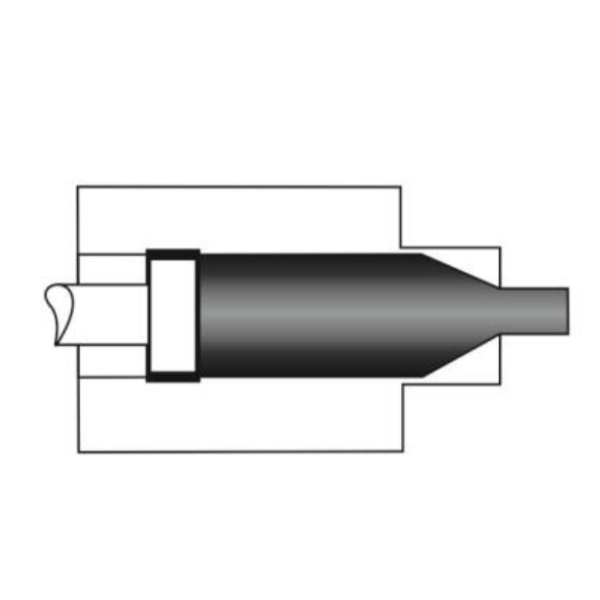

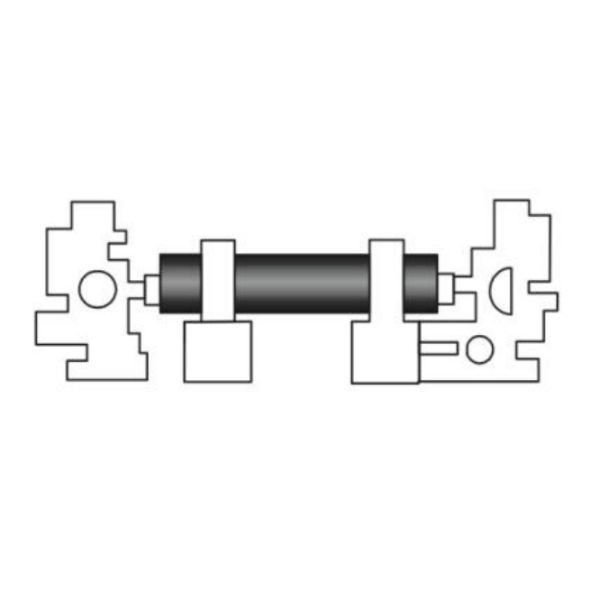

8. Machining (Final Processing)

- The graphitized electrodes are precisely machined (turned, threaded, and tapered) to meet exact dimensional tolerances.

- Surface treatments (e.g., anti-oxidation coatings) may be applied for enhanced performance in high-temperature applications.

Applications of Graphite Electrodes

- Steelmaking (Electric Arc Furnaces)

- Steelmaking ( Ladle Furnaces)

- Silicon & Phosphorus Production